Lightning: A Design Consideration for the New VLJ Composite Aircraft

By Si Robin

VP/CEO of Sensor Systems, Inc.

The era of the VLJ (Very Light Jet) is upon us and many have been purchased for corporate and private pilot flying. These aircraft, having jet capabilities and safety with with prices approaching those of high-end, propellar-driven aircraft, are hanging the shape of transportation, not just air travel. GPS, weather data radios and traffic avoidance systems give us the confidence to fly high with the big boys. All the way up to where lightning lives.

Around the earth there are approximately 100 lightning events per second, which equates to well over 8 million events per day. An estimated 85% are within a cloud or from cloud to cloud. It’s no wonder that large commercial jets are struck by lightning, on average, at least once every year while airborne. Rarely is an catastrophic accident caused by these strikes since the metal skin of the aircraft carries the charge along it until the current exists, generally at the wingtips or the tail.

Carbon fiber and other composite construction air frames generally have a sandwiched layer of conductive mesh to carry “P” static charge build-up and provide some lightning protection. Experiments indicate there are essentially two types of aircraft lightning strikes: aircraft-initiated and aircraft-intercepted.90 % of the lightning events involving aircraft are triggered by the aircraft entering an area which has an intense electrostatic field, generally between 10,000 and 25,000 feet. The other 10% is the interception by an aircraft of a lightning bolt on its way to the ground and are generally the most severe. This is most likely to occur on landings and take-offs at altitudes less than 5,000 feet.

Before the FAA will certify an aircraft for service, it must be satisfied that the aircraft meets all the applicable requirements, including lightning protection. The airframe and avionics manufacturers consider, at the onset, their designs with lightning protection in mind. Composite aircraft require special evaluation to determine the best way to protect against lightning and eliminate any possibility that critical structures and systems will be damaged.

Even though much study has been done on lightning’s effects to aircraft, we still on occasion learn much from field events. As John Wiley cited in his April 2007 article in Business & Commercial Aviation Magazine, on September 6, 2006 the FAA issued an Airworthiness Directive for Embraer’s ERJ-170 requiring replacement of all fiberglass VHF antennas in position one. This happened after an ERJ was struck by lightning and lost all voice communication with the outside world. The fiberglass antenna was unilaterally replaced on these aircraft with an all-metal, DC grounded version patented and manufactured by Sensor Systems Incorporated, the S65-8280-41 model.

Lightning: What is it?

As pilots (and passengers) it is important to learn about this beautiful but deadly natural phenomenon. It is also important to understand where lightning strikes and how it travels along and exists the aircraft.

The Earth is a big electric circuit: electrical energy is continually flowing from the earth’s surface by evaporating moisture into the air in the form of negatively-charged ions. Then back to the earth again in various ways as positive ions. Clouds can be like big batteries, storing electrical energy from the lower negative charge and the upper positive charge just waiting for some hapless plane to enter and short it out. Thunderstorms are generators. Lightning is a massive static discharge.

The majority of lightning events take place in the clouds with some form of moisture present, rain, ice or snow, due to friction between the particles. Lightning’s favorite environment is above 10,000 feet and a temperature between 14-40 degrees Fahrenheit. Give this environment as wide a berth as possible, remembering that lightning can strike up to 10 miles from thunderstorm activity.

If you do take a hit while in the air (you will know), keep flying and try to relax. Barry Shiff, a 30 year TWA pilot, reported in his article in AOPA Pilot last year that “…a strike can sound like someone on the flight deck shot a .45-caliber pistol.”

Lightning is generally associated with thunderstorms and cumulonimbus clouds but can occur anywhere that has a high static electricity buildup due to friction and collision between particles such as in snow storms, dust storms and tornados and even in the ash clouds of volcanoes. None of these are good flying environments and are usually avoided by safety-minded pilots. However, if it is occurring near or at your airport destination, you may elect to land rather than re-route to another airport and deal with the subsequent inconvenience and lost time. Most of the damaging lightning strikes to planes happen on descent for this reason.

When thunderstorm activity is present near the airport, it is not advised to take off and fly in thisweather as we all well know. It’s also a very good idea not to be on the ramp at this time. Airlines will have their ground crew abandon aircraft they are servicing until the danger has passed. The 30/30 rule should be applied here: if you hear thunder within 30 seconds after sighting lightning, get inside of an adequate structure and wait until 30 minutes after you see any more flashes. It’s not a good idea to be standing next to your plane with a stop-watch, though.

While waiting in the hangar for the storm to pass you can review some lightning facts:

- On average, over 70 people a year are killed in the United States from direct lightning strikes.

- The National Weather Service reports over 3,000 cardiac arrest deaths per year are related to lightning strikes.

- More deaths are caused by lightning strikes each year than any other weather related phenomenon except floods.

- Florida has the highest number of lightning strikes and the most recorded lightning deaths.

- The human body is a marvelous conductor of electricity.

Be patient. Wait the storm out. Have a cup of hot chocolate.

Back up in the cloud, the collisions between the moisture particles can cause some to become positive and others to become negative. Particles are very cliquish and separate to be amongst others of their own kind: the positive go upwards, the negative gather at the bottom of the cloud. This is referred to as a “charge separation” and we now have an electric field. This charge separation also happens between the Earth and the atmosphere as the Earth acquires a positive charge. The farther apart the positive and negative particles get from each other, the more potential voltage builds up — thousands of volts per inch! Something’s gotta give.

So now we have the negatively charged area sending out little feelers, called “leaders”, looking for a positive area which responds by sending out their own little feelers, called “streamers”. This is much like how your hair stands on end when close to a static field.

A leader is sometimes called a stepped leader because it flows from its origin to its termination point (a streamer) in quick steps that are about fifty yards long. Each step happens in less than one-millionth of a second and the time between each step is about fifty-millionths of a second. The stepped leader takes about one-hundredth of a second to travel from the cloud to the ground.

A “return stroke” is the actual visible part of the lightning bolt that we see after it makes its initial attachment to something giving off a positive streamer and establishes its path or channel to the oppositely charged termination point. It’s estimated that lightning can travel at speeds over 90,000 miles per second in some conditions. Way too fast for the eye and brain to process.

Streamers can extend from several points on the aircraft before being struck by lightning. The initial lightning contact is referred to as a leader or stepped leader and will connect to one or more of the streamers which will then complete the lightning attachment to the aircraft. One of the other streamers will then become an exit point for the current. Now we have completed a path from negative to positive. This now becomes a channel for the actual current of the lightning strike.

The path that the lightning current takes from its initial attachment to its exit is called the swept channel since the current seems to sweep over the surface of the aircraft. The stroke itself is called a swept stroke. In reality, the stroke is relatively stationary with the plane moving through the flash. The arc can reattach itself numerous times along the channel until it exits and is a function of the conductivity of the aircrafts surface.

To clarify this, if the initial lightning attachment was on the nose of the aircraft, the forward travel keeps it moving through the established lightning channel but the lightning current would stay (dwell) at the attachment point. Since the aircraft is continuing to move forward through the lightning strike, the current is pulled out over the surface then reattaches at a new point more convenient for it (lightning can be lazy). If the surface is very conductive, it will not stay at one point (called dwell time) but move rearward to a new point its chosen, perhaps another streamer.

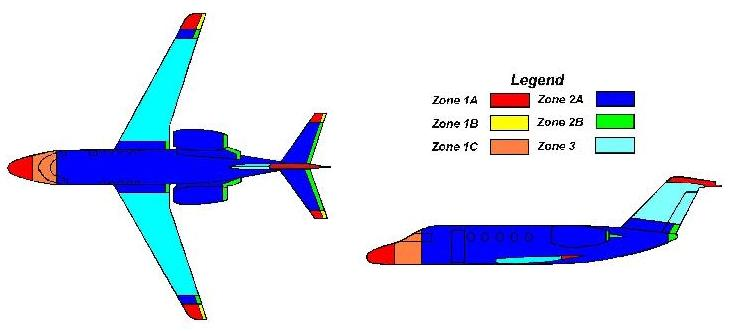

Aircraft Lightning Zones

Typically aircraft are divided into three lightning zones which describe an expected current conduction potential and duration in relation to a strike attachment. Specifics are generally addressed in the airframe manufacturer’s manual. The zones help the design engineers determine the type of protection which will be required and also for analysis and reporting after the fact in the case of a strike. These zones are developed for individual aircraft by testing on scale models and by comparison to established zones for similar aircraft and may also include sub-zones (A, B and C).

Zone 1: Direct Stroke Attachment Zone

Regions likely to experience initial lightning attachment and first return strokes. This zone includes the wingtips, various projections such as the nose cone, the tips of the

horizontal and vertical stabilizers, the trailing edges of the horizontal stabilizer and the tail assembly. Cockpit window frames could also be considered in this zone, depending on design. Lightning has been known to attach to zone 1 areas and remain attached for the entire duration of a stroke. This is generally measured in microseconds but has, on rare occasions, lasted over one full second (lightning can burn through quarter-inch aluminum in 20 microseconds). Any other projecting parts (such as antennas), might also constitute a point of direct stroke attachment. Landing gear deployed on final approach would be in this category.

Zone 2: Swept-Stroke Attachment Zone

Regions which are unlikely to experience first return strokes but are likely to experience subsequent return strokes.

Sweptstroke surfaces are surfaces for which there is a possibility of strikes being swept rearward from its direct stroke attachment due to the aircrafts movement forward. This zone includes fuselage surfaces.

Zone 3: The Remainder of the Aircraft

Zone 3 includes all areas not covered by Zones 1 and 2 and has a low probability of any direct attachment, however may carry substantial amounts of electrical current between the direct or swept-stroke attachment and exit point.

Zones 1 and 2 may also be divided into regions A, B and C regions. The A regions have a low probability of the arc hanging on and may include the nose and wing mid-span areas. The B region has a high probability of arc hang-on, such as the tail cone and wing trailing edges. The C region is in Zone 1 and is a transition zone for the first return stroke.

Typical VLJ Aircraft Lightning Strike Zones

Typical VLJ Aircraft Lightning Strike Zones

Aircraft Protection Methods

There are a number of different protection methods utilized to protect aircraft from the effects of lightning strikes depending on what needs to be protected. Protecting against direct or indirect effects of lightning currents will dictate the types of protection required.

Direct-effect damage results from the lightning attaching to the aircraft and its subsequent flow through the structure. The extremely high current (up to 200,000 amps) can melt aluminum and burn composite material at the attachment point. Current flowing through the structure may cause sparking at joints. For metallic skinned aircraft, design criteria have been developed which call for minimum skin thickness to prevent burn-through. Fuel tank safety is addressed by using low-resistance bonding methods to prevent sparking in high resistance joints and interfaces.

The composite materials being used in new VLJ’s have high strength and low weight properties making them ideal structural materials: a lighter-weight airplane uses less fuel and requires less power to move them. However, their electrical properties offer little to no lightning protection. Graphite epoxy is about 1000 times less conductive than aluminum and Kevlar epoxy and fiberglass are not conductive at all, essentially invisible to electric current. VLJ’s made of composite materials have metallic fibers or mesh embedded in them to minimize direct-effects damage. A particularly hard strike may necessitate repair/replacement of the mesh material at

lightning attachment and exit points. A walk-around inspection will reveal these sacrificed regions and it would be well to take care of them before making another flight.

Whether it’s a metallic aircraft or a composite with embedded wire mesh, the structure and skin establish what’s called a Faraday cage effect which passes the current along the outside of the aircraft and protects the human passengers and equipment inside. Some aircraft have a plastic material nose cone with a weather radar antenna mounted behind it. Metal diverter strips are mounted on the outside of the nose cone in a pattern that doesn’t interfere in the operation of the radar, but will protect the antenna by conducting the lightning current into the airframe.

Damage also could result from lightning’s indirect effects which are transient pulses produced by the electric and magnetic fields generated by current flowing through or near to the aircraft structure, wiring, hydraulic lines, and electrical or electronic equipment on board. Special shielding, insulators, isolators and grounding techniques are used to protect against damage or upset from these indirect effects.

Protection from the indirect effects of lighting on avionics systems becomes crucial when these systems are installed in aircraft made with non-metallic composite materials. Avionics systems operating on low voltage can be very sensitive and susceptible to damage or disruption from lightning induced transients if these systems were not protected. System wiring can be protected by routing it near any metal in the structure and shielded with wire braid or foil. The system units themselves are protected internally and externally by various methods mentioned above.

All in all, aircraft are protected extremely well from lightning strikes causing catastrophic damage or death. They haven’t blown up or crashed in the U.S. due to lightning strikes since the FAA and others put stringent requirements on airframe and avionics design.

In 2003 Rob Majkner of Sikorsky Helicopters published articles pertaining to helicopter lightning protection as they present a unique consideration since their construction combines composite materials and an aluminum structure with rotating components. The current design of helicopters has multi-function avionics with flat panel displays that may be susceptible to high current inputs.

This article was written to provide guidance for new composite aircraft in the consideration of safety for air frame and avionics.

Si Robin has been flying since 1955 and, at age 80, maintains a private, multi-engine, instrument, land seaplane rating and appeared in the movie “One Six Right.” He is also CEO of Sensor Systems Incorporated, a major supplier of TSO antennas for commercial and military aircraft.

What is smaller than a silver dollar but can reach over five miles in length, raise air temperature up to 50,000 degrees, carry a hundred million volts and completely mess up a good paint job?